The latest 6 or 8 tests resulted in the motor failing to light, or

lighting in strange ways. This web site hasn't been updated in a while

because watching a tank fill and then vent is boring.

Hopefully the following methods will prove reliable and repeatable.

36" length x 3" diameter N2O tank with 12" dip tube installed. 18" length x 2.75" OD x 2.00" ID PVC grain. Graphite nozzle, 1.20" throat, 15 degree egress, 60 degree ingress. Tank pressure actively regulated to 400 PSI. |

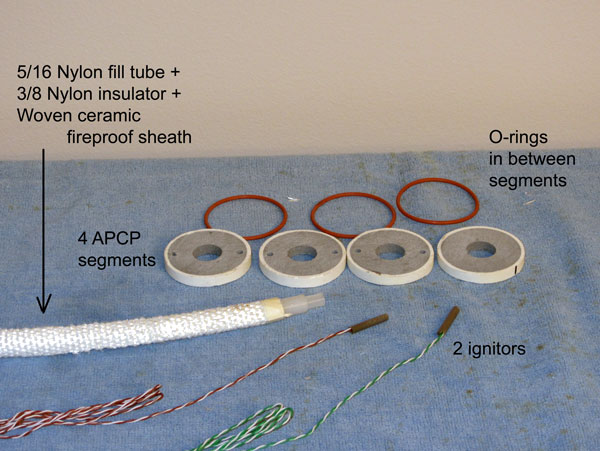

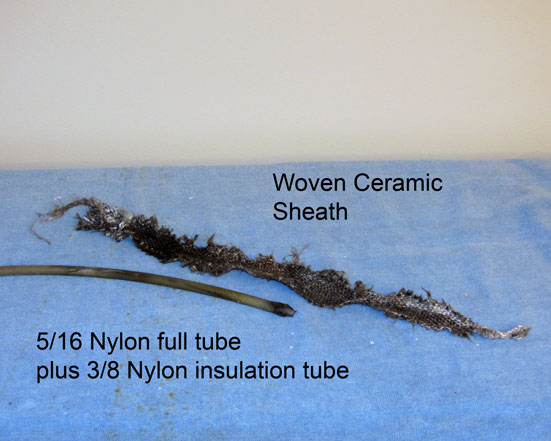

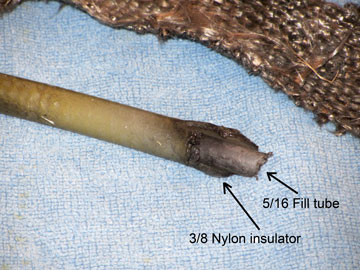

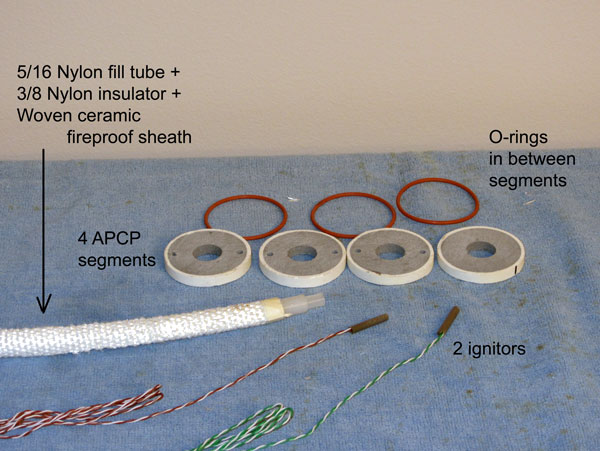

Delay burn-though of the Nylon fill tube so the pre-heater is burning vigorously. In previous tests, the fill tube cut early in the ignition process and the flowing Nitrous would actually extinguish the burning APCP grain!! The delay is accomplished by shoving the 5/16" Nylon fill tube into a second 3/8" Nylon tube. The outer tube acts only as an insulator.

In addition to the insulator, the two Nylon tube are protected by a woven ceramic fireproof sheath. Previous tests used a fiberglass sheath, but the woven ceramic should offer greater flame protection.

The pre-heater itself is broken into four 1/4" segments. Sacrificial O-Rings are put in between the four segments. The only purpose of the O-Rings are to provide spacing. The ignitor is a 1" commercial eMatch. Three of the four segments are lit and the flame front should progress quickly over and in between the segments. There should be a radial component of the frame front in the configuration.