Possible solution: Decouple the N2O tank from the chamber by using a flexible hose instead of rigid pipe.

I couldn't find a pre-made stainless steel braided hose which met my requriements, so I bought the parts and assembled my own. Not a big deal usually. Of course this time one end of the hose just wouldn't fit into the end connector. The solution... boil.. and pound.. boil.. and pound!

The fittings are -12AN connected to 3/4" nylon lined braided SS from http://www.anfittingsdirect.com. AN fittings are a pleasure to work with compared to NPT.

The new right angle connection.

All the parts.

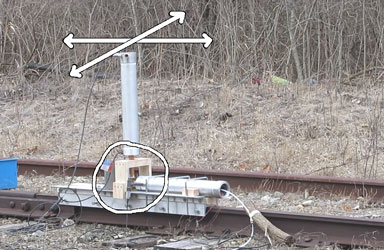

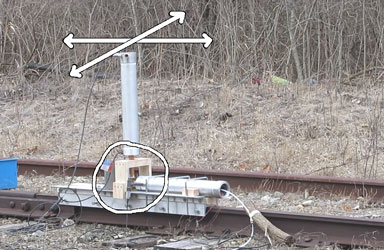

I didn't have enough nitrous for a complete fill. Instead of purging the gas, I pushed the button. No data.. just fun to watch.

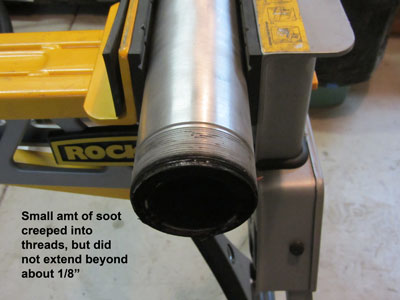

The chamber pressure is too low. I believe (a) One of the injectors clogged (b) I pushed the limits on ambient temperature. I'm sure this design will operate to 32 degF, but the air temperature was below 30 degF. The trace of the entire timeline sort-of confirms this.

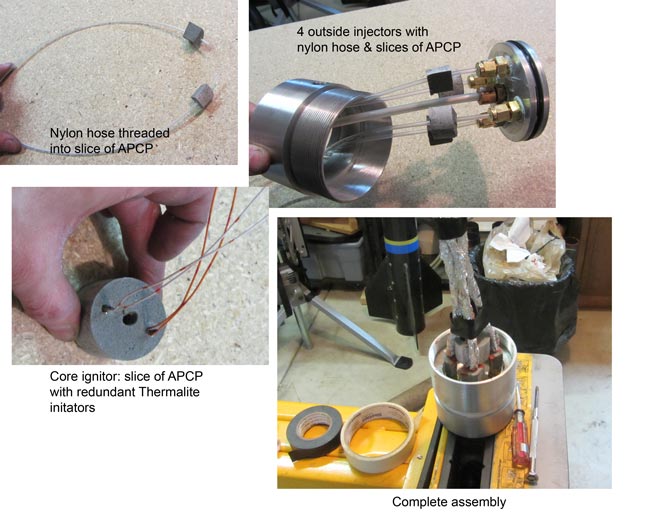

Like previous motors, slices of APCP were used as a pre-heater and main motor ignitor.

Im still not satisfied with the reliability and repeatability of igntion. A dozen tests of different ignitor configuratons were run and filmed with high speed video.

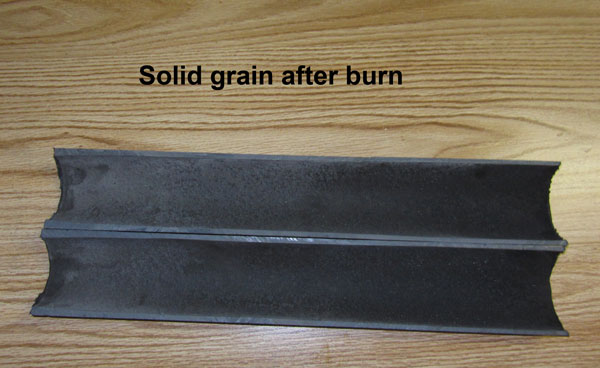

Theory: the timing of the ignitor and the opening of the UC valves is tight. While a Pyrodex pellet looks like a huge ball of fire to the naked eye, high speed video reveals that burning Pyrodex is consumed in 300 mSec to 500 mSec. At the other end of the spectrum, an APCP slug takes several seconds before it is fully burning.

Possible solution: use APCP, but strategically place the thermalite initiators.

Double Pyrodex pellet taped together with electrical tape. (Contrail approach) Notice the nylon tube did not melt.